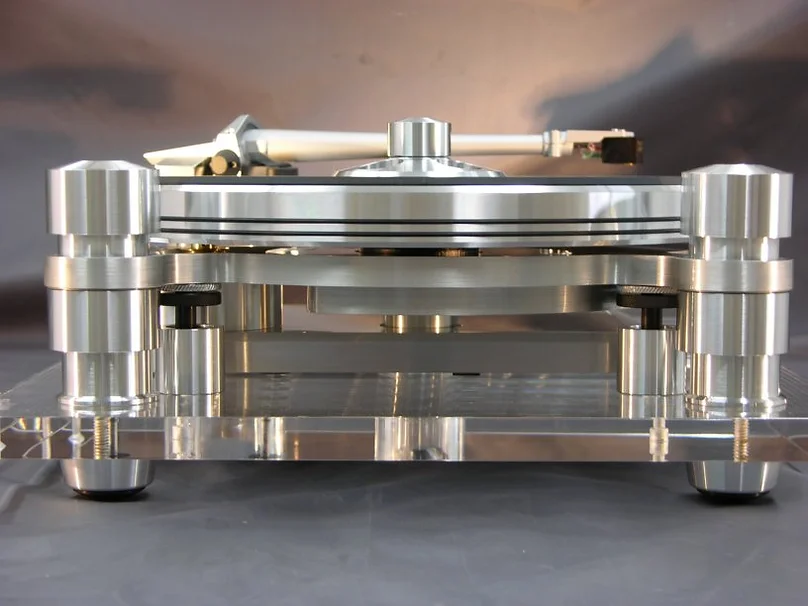

Oracle Delphi MK VII Classic Turntable

$13,175.00

-

Free Shipping

-

About the Delphi Mk VII Classic

Since 1979, Oracle Audio has been producing state-of-the-art stereo components. Oracle’s first turntable, the Oracle AC, introduced new standards to the analog world and rapidly became athe new reference. Oracle’s Delphi Mk I was introduced in 1980. Today, the Delphi Mk VII is the seventh edition of the Oracle line heritage. Through the years the Delphi won numerous prestigious awards and it has been acclaimed worldwide! Having appeared on the more than 50 magazines cover pages worldwide the Oracle is a true icon. The Delphi Mk VI was awarded the Analog Grand Prix 2010 Gold Award from Japan, more recently Enjoy the Music.com “Best of 2014 Blue Note Award” and the “Best of Toronto 2022”. In 2020, the Oracle Delphi Mk VI was awarded the “Legendary performance 2020” By the Enjoy the Music.com magazine. To this day the Delphi is still Oracle’s flagship product and still serves as a reference in the analog community!

Using the finest components and design technologies, the Oracle Delphi Mk VII is exquisite in all aspects. Like its predecessors the Delphi Mk VII is supported by three suspension pillars to efficiently control unwanted vibrations. It harbors a massive belt-driven platter that uses our famous record clamping system which was first introduced by Oracle back in 1979. The Delphi’s floating chassis, milled from solid billets of 6061T6 aluminum/magnesium alloy, is an extremely rigid and inert structure supporting the tonearm and the platter. While the fabrication process of the Delphi is one of minute precision its development process is one of science that brings out all of the music’s depth, details and emotion.

Truly the Delphi is a Work of Art so, what’s new with the Mk VII ?

Since the introduction of the Delphi Mk VI in the fall of 2009 featuring the innovative Micro Vibration Stabilizer System (MVSS) we never really stopped with new developments. During the summer 2015, we introduced the Mk VI Second Generation featuring the new two-piece platter assembly which greatly facilitates the drive belt installation while also reducing platter resonances. By not having to remove the inner platter to install the drive belt the main bearing accuracy is preserved. With a now lighter inner platter/spindle assembly we were able to further improve the main bearing design and make is calibration even more precise. The trust plate supporting the platter spindle Tungsten carbide ball tip is non-metallic and made of Glass Filled Torlon. The dual tripod main bearing design is using 6 precision PEEK screws, 3@120 degrees apart at the top and 3@ 120 degrees apart at the bottom of the bearing assembly, those are offset @ 60 degrees with the top screws. The AC synchronous motor uses impedance matched internal windings. The Mk VII motor drive module is a precision frequency generator using Military grade high precision capacitors to further smoothen the sinewave feeding the motor coils. A precision calibration stage has been implemented to the drive module so we can precisely adjust the positive and negative sinewave voltages feeding the motor coils further reducing vibrations. The final and key element of the new Delphi Mk VII is the Turbo Mk II power adaptor which has been further improved. A fine trim potentiometer allows a precise calibration of the output voltage to 24.35 volts DC. The elaborate drive system of the new Delphi Mk VII has been designed so each critical steps can be precisely calibrated to aligning with a very high level of accuracy with the ultimate goal being to make the AC synchronous motor spin smoother and more accurately with less vibrations. All the settings described above are done at the factory so our customers do not have to worry about them, the main purpose of the Delphi Mk VII is to provide to you the user with pure visual and musical enjoyment.

The new Delphi Mk VII sonic performance delivers a higher level of dynamic contrast and vastly improved inner details with a transient response resulting in a remarkable ability to preserve and deliver the harmonic structure of the music. Driven by our new Turbo Power Supply Mk II the Delphi Mk VII will transform your listening sessions into unforgettable lifelike experiences.

Using the finest components and design technologies, the Oracle Delphi Mk VII is exquisite in all aspects. Like its predecessors the Delphi Mk VII is supported by three suspension pillars to efficiently control unwanted vibrations. It harbors a massive belt-driven platter that uses our famous record clamping system which was first introduced by Oracle back in 1979. The Delphi’s floating chassis, milled from solid billets of 6061T6 aluminum/magnesium alloy, is an extremely rigid and inert structure supporting the tonearm and the platter. While the fabrication process of the Delphi is one of minute precision its development process is one of science that brings out all of the music’s depth, details and emotion.

Design & Technology

The global concept of the new Oracle Delphi Mk VII, now in its 45th year, was developed around the control of micro vibrations and micro calibration. The micro vibration can be introduced from the inside as well as from the outside. We have to understand that the micro movement of the phono cartridge’s stylus is extremely vulnerable when capturing the minute deviations from the record groove. At the same time this stylus is extremely powerful because it sends through the system a vibrational energy that can and will stimulate other vulnerable components. This will also translate into resonances.

How can it happen?

Resonances generated by the tonearm bearings and the tonearm tube will go back all the way to the stylus and induce a coloration that is in no way related to the music being reproduced. Tonearm bearings play an extremely important role in the quality and integrity of the signal reproduction. Any micro movement within the tonearm bearings will also translate into a mechanical cancellation (two objects moving simultaneously in opposite directions). This means that the stylus will not capture all the micro signals engraved on the vinyl recording.

When we think about the vibrational energy generated from the outside of the record player it is extremely difficult to identify all the sources that can affect the system but it is possible to regroup most of them into 3 categories: electrical, mechanical and acoustical. I will not address the electrical aspect here. For the other two categories the best option would be to completely isolate the player from the sound room in order to protect it against the sound pressure level. As for vibration, the use of an extremely massive platform would help keeping the unwanted mechanical energy outside of the picture. This would not be realistic and certainly not aesthetically successful! The magnetic isolation can be a solution but at the same time it can be a significant part of the problem.

What changes have been made to the drive modules?

The Delphi Mk VII is a work of technical development and design aesthetics. As far as the aluminum drive module is concerned there was no cosmetic change from the visual balance we created with the Mk VI. The major change on the motor circuit from the Mk VI is the motor coils voltage offset precision calibration and the use of military grade coupling capacitors to further smoothen the motor pulsations thus reducing vibrations which have been implemented to the a surface mount drive electronics configuration. We use a low voltage precision AC synchronous motor with impedance matched coils on the Delphi Mk VII.

What is the influence of the bigger sub-chassis on the performance of the Mk VII?

The floating sub-chassis of the Delphi Mk VII is no different from the MK VI. It was made larger than its predecessors which improved the weight and mass distribution making the suspension calibration more efficient and accurate. The purpose of the sub chassis counter-weight is to add more mass to the front left suspension tower to more efficiently counter-balance the mass of the tonearm. The coupling of the counter-weight to the floating sub-chassis also contributes in reducing internal sub-chassis resonances. Its positioning, well in sight on the inferior part of the sub-chassis, is a design detail meant to bring the Delphi a more massive look. The central part of the floating sub-chassis was made larger which had for effect to reduce the length of the three legs extending towards the suspension towers. We also increased the rigidity of the tonearm mounting section by widening the tonearm mounting ring support by about 35 percent.

How does the Mk VII bearing system differ?

The Mk VII bearing system maintained the 6 point contact configuration that was developed for the Mk V. The trust plate supporting the platter spindle Tungsten carbide ball tip is non-metallic and made of Glass Filled Torlon. The dual tripod main bearing design is using 6 precision PEEK screws, 3@120 degrees apart at the top and 3@ 120 degrees apart at the bottom of the bearing assembly, those are offset @ 60 degrees with the top screws.

What is the impact of the two piece platter and the new Main bearing system?

This allows us to calibrate the main bearing system with greater accuracy and closer tolerances. This has a huge and direct impact on the signal reproduction quality of the Delphi Mk VII. The bottom trust plate is now made of glass filled Torlon which is a polyamide-imide (PAI) high strength plastic with the highest strength and stiffness of any thermoplastic. It has outstanding resistance to wear. The impact of this new trust plate is extremely significant on the sound quality because of its ability to limit the noise generated by the spinning platter. The sonic benefits of the new Mk VII bearing system are extremely significant and they are drastically revealed especially when in combination with the micro-vibration stabilizer system (MVSS).

How significant is the Micro Vibration Stabilizer System?

The Micro Vibration Stabilizer System is the single most significant and most efficient improvement made to the Oracle turntable since its creation 35 years ago! The MVSS system represents the final barrier to the elimination of the micro vibrations. This system will virtually eliminate the access of micro vibrations to the most critical part of the turntable, the sub-chassis, tonearm, phono cartridge and platter assembly.

What is the purpose of the MVSS?

The purpose of the MVSS is to capture and dissipate the micro vibrations that are present within the floating sub-chassis without short circuiting the efficiency of the Oracle suspension system. By eliminating the micro vibrations the stylus / platter interaction becomes more accurate, the stylus becomes more stable and better controlled. This increased stability allows the phono cartridge to retrieve more information from the record groove which translates into a more accurate signal reproduction which will not only impact the lower register but the whole spectrum. This global improvement will be very noticeable at all levels: improved musical accuracy, harmonic integrity, transient’s sharpness, dynamic contrast, tonal balance, depth of image. The listener suddenly becomes more musically involved and this is a very unique experience!

How does the MVSS system control work?

Beside each suspension tower a small reservoir is secured to the acrylic base of the Delphi. They are filled with an extremely low viscosity silicone fluid. Again, near the suspension housings a threaded stem is mounted to the bottom section of the sub-chassis, those are lining up with the silicone reservoirs, a threaded lock nut and a tapered shape plunger will complete the mechanism. Once the tonearm and cartridge are precisely calibrated, the suspension system perfectly adjusted the turntable is ready to operate. The plungers on each sub-chassis leg are now lining up with the reservoirs mounted to the acrylic base. When in the fully up position the plungers do no come in contact with the silicone fluid in the reservoirs.

It is then possible to play your Oracle without the MVSS in operation. Then experiment with the calibration of the plungers by turning them clockwise when viewing them from above the turntable as reference. Each full turn will generate a plunger displacement of 1,27mm (0,050”). The same calibration should be done for each plunger. Since we are dealing with micro vibrations it is extremely important to lock the plunger in position with the locking ring. Moving the plungers by one turn increments will reveal how they influence the performance. At the factory the best results were achieved between 1½ and 2 full rotations of the plungers. This represents a plunger penetration from 1.90mm à 2.54mm 2,80mm into the silicone fluid. We also believe that the ambient temperature has little influence on the depth calibration of the plungers. The type of support furniture or the nature of the flooring may require some fine tuning of the calibration. The MVSS calibration is done by listening to music so it is in fact a matter of finding the sweet spot where we get the best equilibrium.

What about the new Delrin adjustable feet?

On the Delphi Mk VII. there has been no change from the Delphi Mk VI Delrin adjustable feet system. In our quest to further increase the performance level we did not hesitate to challenge each of the systems we had in place on the Oracle Delphi. Extensive testing and listening test convinced us that the use of Delrin was extremely beneficial to the performance of the turntable. We found the new Delrin adjustable feet to provide a better sonic balance with all the different equipment racks it has been tested. This new system further improves the natural tones of the instrument and voices. In fact, it is the whole musical spectrum that is gaining from this new system!

Has the power supply been changed at all?

The basic version of the Delphi Mk VI comes with a simple and efficient power supply. The Turbo Power Supply Mk II is optional but highly recommended as it brings a substantial improvement to the performance level of the Delphi. Its DC power cord is made out of highly performing monofilament thread. What contributes the most to the sonic improvement we get from using the new Turbo Power Supply Mk II is the reduction of the parasitic noise (ripple) to less than one millivolt, down from 120 millivolt ripple in the signal of the previous Turbo Power Supply Mk I version. The latest version of the Mk II Turbo power supply used in the Delphi Mk VII is using a precision voltage calibration circuitry and the output voltage is calibrated to 24,35 volts DC.

Features & Specifications

Suspension:

The Delphi sub-chassis / platter / tonearm assembly is suspended by a tripedal mounting, which eliminates room vibrations. Each suspension tower assembly combines 12 different components, using 7 different mechanical filters, all working as a whole to efficiently control unwanted vibrations.

Bearing assembly:

The traditional two bushing system has been replaced by a new system using six precision surfaced nylon screws. With this, Oracle reaches the highest level of rotational accuracy.

Motor drive electronics and drive belt:

Oracle selected a specially designed AC synchronous motor. The Delphi Mk VII features a dual current drive circuitry. This provides maximum start-up torque energy and minimum efficient operational energy, which guarantees lowest possible motor vibration. The molded belt plays an important role in maintaining maximum speed stability.

Record / Platter:

The maximum rigidity of the 4kg (8.8 pound) platter is immune to vibration by distributing most of the mass around its outer edge. The flywheel effect increases momentum. Record coupling system (standard): Oracle pioneered the now well established “record clamp system” to solve specific vinyl disc “warp” problems.

Hard acrylic mat:

The Oracle acrylic mat made from specially formulated polymer shows better matching characteristics (impedance) with the vinyl disc.

Sub-chassis:

Oracle demonstrates that superior engineering can also be aesthetic. The hand brushed aluminum with a clear lacquer coated skeletal sub-chassis will dissipate unwanted energy through efficient coupling and clamping methods. Maximum rigidity, minimal surface area and energy control are key design.

Plinth:

The standard plinth is Clear Acrylic. An optional Black Granite plinth is available for an extra charge.

Power Supply:

The Delphi Mk VII comes standard with a regular power supply. The optional Turbo Power Supply MkII is the result of an extensive development and performance comparisons between reference elements such as special batteries and monstrous power source. The Oracle Turbo Power supply outperformed them all! The turbo power source transforms an outstanding performance into a wonderful musical experience. Both power supplies ship with a removable power cord.

Oracle Reference 1 tonearm (Optional):

The Oracle Reference 1 tonearm is a currently under development and will be available in June 2023. More information will be published soon.

Dimensions: 363 X 475 X 150 mm

14.5 X 19 X 6 in

Weight: with acrylic base: 16 kg – 35 pounds

Acrylic Dust Cover: Clear acrylic dust cover with aluminum hinges or full (dome style) acrylic dust cover are available upon request at an additional cost

Reviews

There are no reviews yet.

You must be logged in to post a review.

Reviews

There are no reviews yet.